Some time ago considerable concern was expressed by Mrs F M Childs regarding the fire hazards associated with computer tapes, and their storage and protection. At the time Mrs Childs was responsible for many of the tapes stored in the basement of Building R3 at the Rutherford and Appleton Laboratory.

I considered her concern was well founded but in spite of much searching I was unable to obtain any practical or test information on these points, so I decided to organise a test burn and to invite any interested persons as observers.

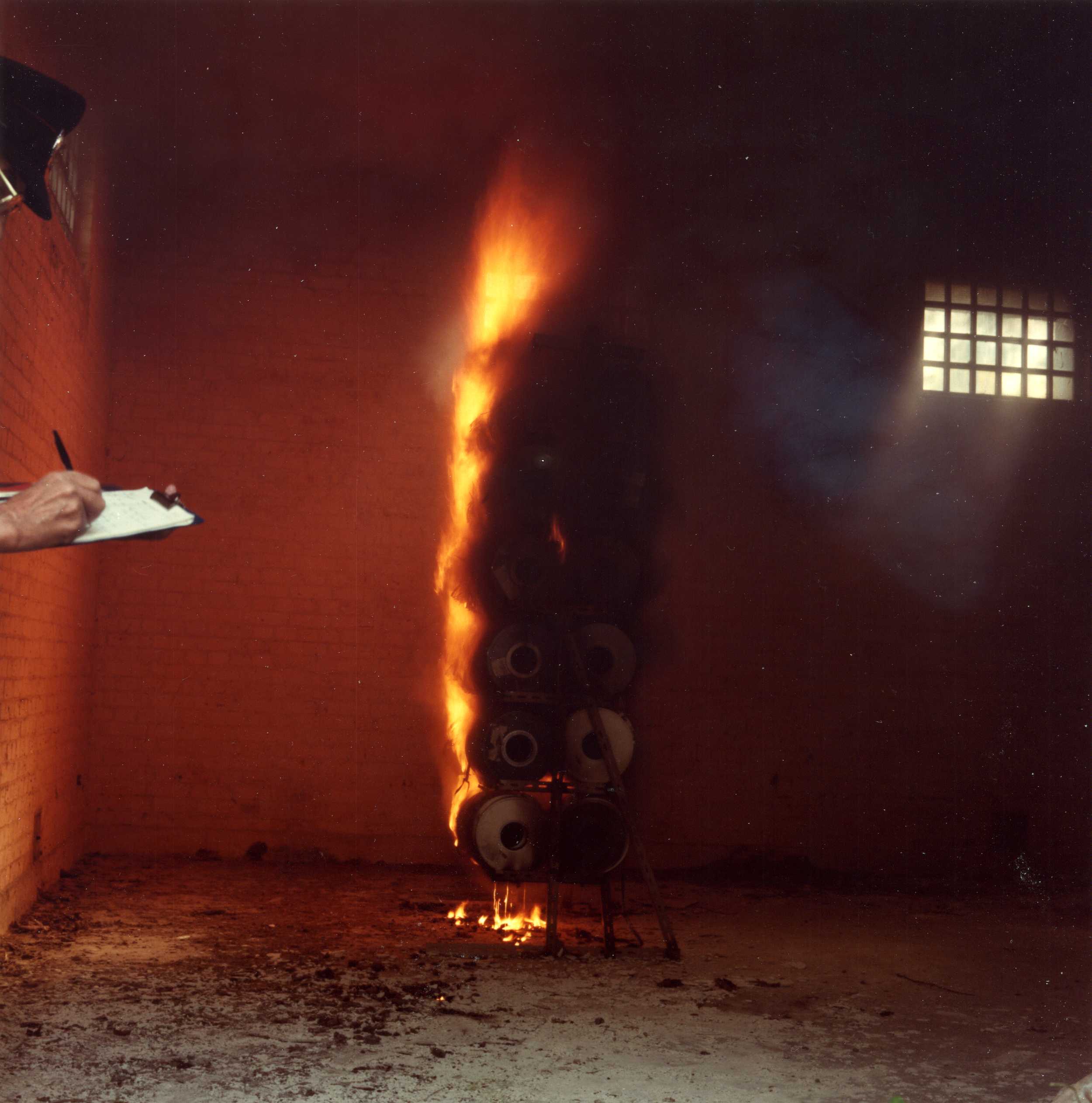

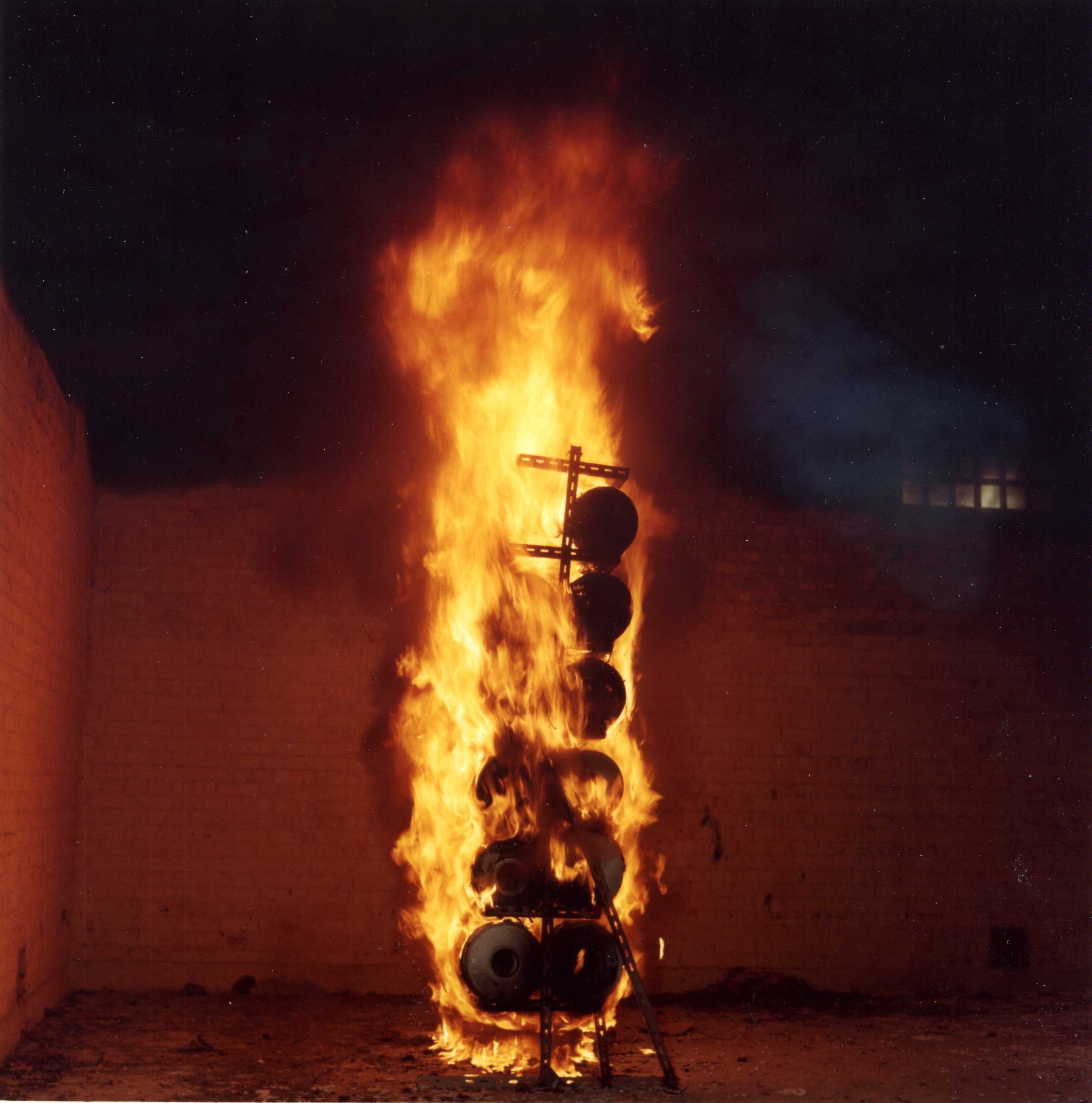

A rack was constructed from Dexion to exactly duplicate the sizes of a standard tape storage rack. This was then loaded with approximately 400 scrap tapes (see photo 1).

The test was carried out on July 4th 1985 at the storage depot, Chilton; this was once a bomb storage depot in RAF days and proved to be an ideal site.

The building used was an old store approximately 22 ft square and 16 ft high. The front wall contained three pairs of double doors each about 5 ft wide and 12 ft high; two pairs were rusted open and the centre pair were rusted shut - so nothing could be done to alter the situation.

The progress of the fire was timed and recorded by Station Officer G J Duffin and a photographer was present. I shall attempt to relate this report with the attached photographs as accurately as possible.

There was a fire appliance and crew standing by throughout the test just in case anything should go wrong as no-one had any exact idea of what was going to happen.

The bottom row of tapes was ignited using a petrol-soaked rag on a steel bar (see photo 2).

Photos 7 and 8 show how the smoke had now built down to a solid layer on the floor. Photos 9 and 10 show how much was escaping through the open doorways. Photo 11 shows a smoke/steam mixture escaping from the building following the initial knock down using high pressure fog.

Photo 12 shows a similar situation following the second knock down.

Photos 13 and 14 show tapes which were recovered after the initial attack; it will be seen that the tightly-wound tapes were hardly affected by the fire - but were, of course, useless, but damage was sustained by the plastic case.

All concerned were most surprised at the rate the fire spread and intensified, by the amount of heat generated and by the vast amount of thick heavy black smoke that was emitted. Had this situation occurred in a poorly ventilated area effective fire-fighting would have been virtually impossible.

The tapes which remained in the racks were welded into tubes which continued to burn on all surfaces including the centre which was almost impossible to extinguish. The effect of the cold water was to solidify the plastic and the tubes had to be broken apart with pick-axes before further extinguishment could take place.

Various extinguishing media were tried. CO2 had no noticeable effect; BCF showed good results but only a small amount was applied. High pressure fog had the most effect but the problems arose that where tapes had been spilled on the floor in a haphazard fashion due to the collapse of the frame, penetration by fog or jet proved almost impossible because the gaps between tapes were often covered by another tape. Any fire involving a stack of tapes would have to be tackled initially from at least two directions.

Whilst the tapes were not greatly affected by the fire, I believe this was due to the fact that the tape is very tightly wound and the fire was not allowed to run its course. It was observed that any pieces of loose tape did burn with the evolution of black smoke. I feel sure that if the fire had been allowed to burn to its natural conclusion the tapes would have burned in from the surface and probably burned for days.

We have to accept that for reasons of economy, logistics and availability control, tapes have to be stored in large numbers and close together. This test has shown us the type of fire spread we could expect. I believe the only types of fire damage reduction systems of any use would be automatic ventilation and an automatic sprinkler system. Thought should be given to this type of protection for large scale tape storage.

The only immediate steps to be taken should be to reduce any risk of ignition to the bare minimum, by careful checking of electrical equipment, including lighting and heating and by keeping any combustible material to an essential minimum, in a word - housekeeping.

It is proposed to carry out a further test in the near future when the emphasis will be on applying various extinguishing media and noting their effect.

This test will be video-recorded and will be made available to Chief Fire Officers on all sites.

G M Rodda

Chief Fire Officer

29 July 1985