The ESPRIT I Project 962, called EVEREST (European Venture for Research in Semiconductor Technology), started in 1986 and had ten partners from five countries with RAL as the Prime Contractor. Its objective was to develop robust and efficient algorithms to simulate the simulate the steady state and time-dependent behaviour of three dimensional semiconductor devices. Once defined, these would be incorporated into a computer code and the results would be compared against measurements on real devices. The project was funded initially for two years but eventually ran until 1991.

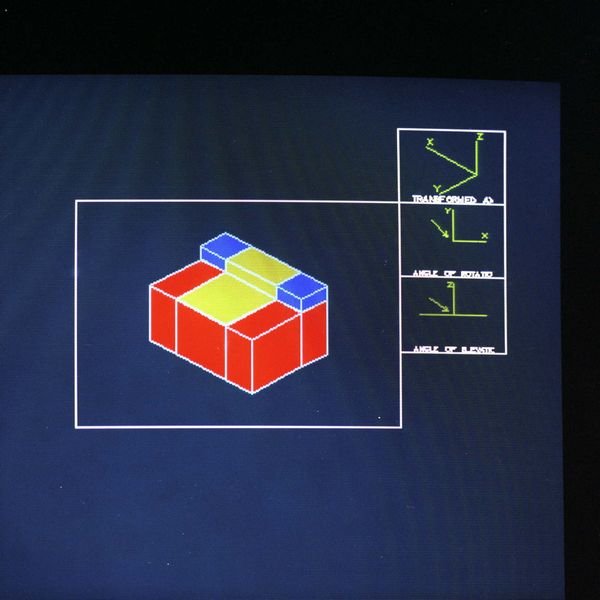

RAL had responsibility for the specification and design of the software system. The software was divided into four parts, the Pre-Processor (Trinity College Dublin), the Doping Profile Generator (University College, Swansea), the Analysis Code (RAL/GEC) and the Post-Processor (UCS). RAL was also responsible for the kernel and for linking the modules together. The linkage used was developed from the existing electromagnetic software developed at RAL.

The complete set of partners were:

GEC was an original member of the Consortium but dropped out during the life of the project.

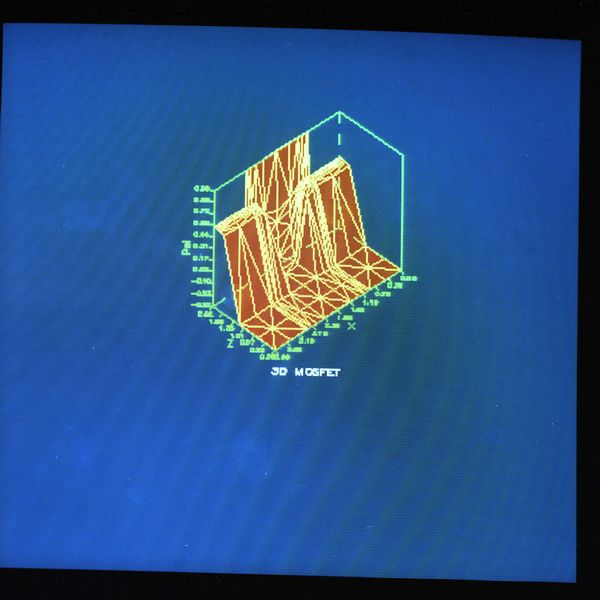

The EVEREST code eventually consisted of over 100 000 lines of Fortran. Starting from a set of partial differential equations describing the current flow within the device, these were solved using a mixed mesh of tetrahedral and hexahedral elements. The non-linear nature of the equations required a flexible solution strategy to be used to make the software robust and efficient. Within the solution process , a large sparse non-symmetric linear system was solved using iterative solvers with preconditioning. Run times varied from many hours to days when simulating realistic devices.

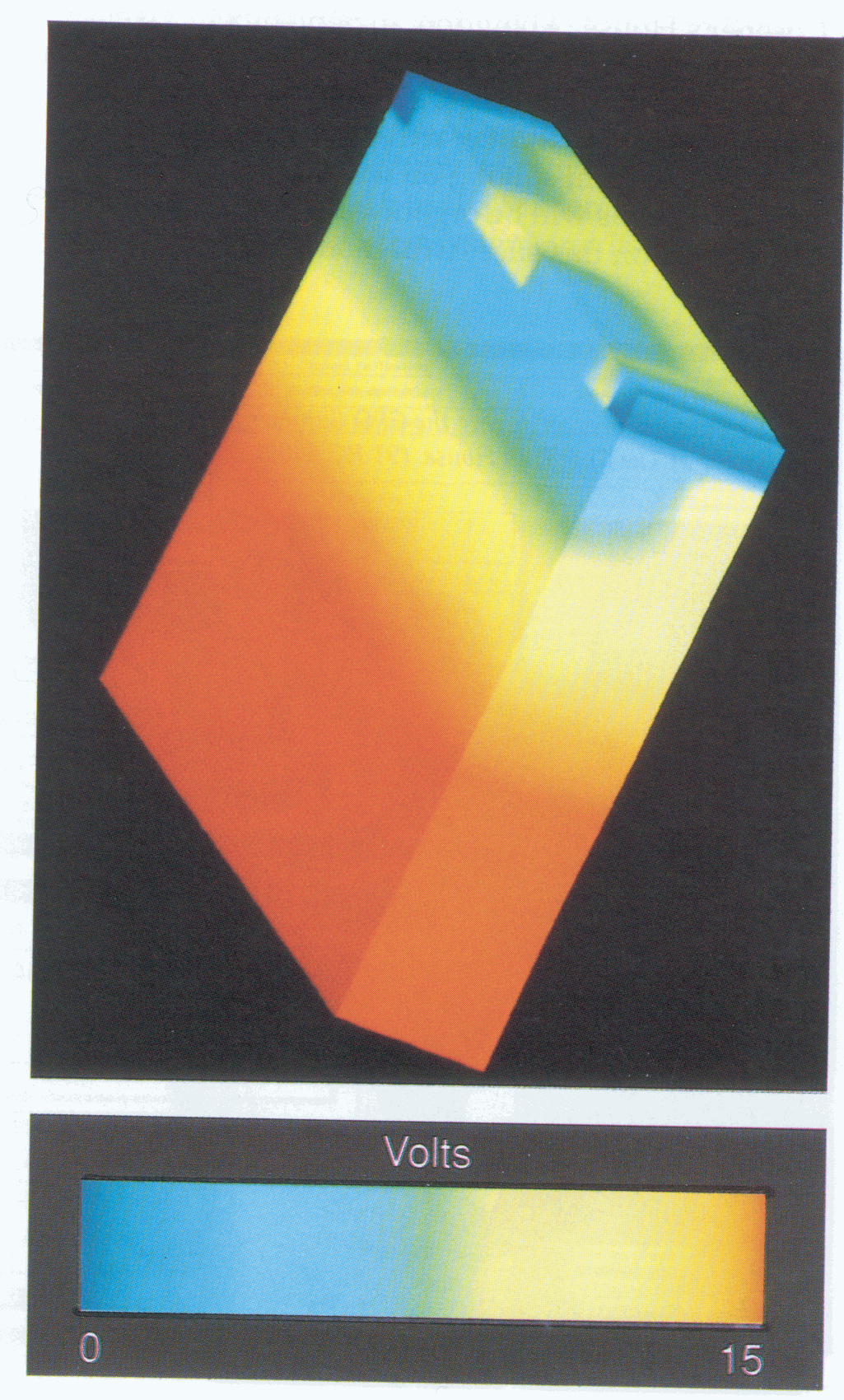

The EVEREST project brought together three of the major European industrial device manufacturers with experts in mathematical modelling and software development. The project significantly improved the understanding of the physical models used to describe the electrical behaviour of devices and developed a full 3-D simulator which could perform both transient and steady-state device analysis. A major advance made by the project was in the use of adaptive meshing techniques during the solution process. As computation proceeds, the EVEREST simulator estimated the error in the solution and enriched the finite element mesh used in areas where this error was large. This type of adaptive solution process was essential for cost-effective 3-D simulation. During the project the simulator was tested and evaluated by the industrial partners by simulating the electrical behaviour of complex device structures such as the charge-coupled devices (CCDs) used in video cameras (see below). In these simulations the 3-D capability of EVEREST was essential to understand the operation and to optimise the performance of these types of device. On completion EVEREST was one of only four 3-D simulators available world-wide and, although others appeared later, it ranked as one of the most advanced for quite some time.

RAL made the simulator available to the UK academic and industrial community. The EVEREST software was distributed to many institutions within the UK. Development of EVEREST continued for some time after the project completed going through four main versions. These extended the range of device structures it could simulate and incorporated state-of-the-art visualisation tools to help users gain insight into the results of the simulations.

See also: