Chris Greenough was Project Leader on the Alvey Process and Device Modelling Projects (ALV/VLSI/APP/034 and 066). The two projects developed the TAPDANCE integrated software environment, a suite of software for 2-D Process and Device Modelling.

John Ashby joined in January 1986 and was involved in the technical development and management of the projects.

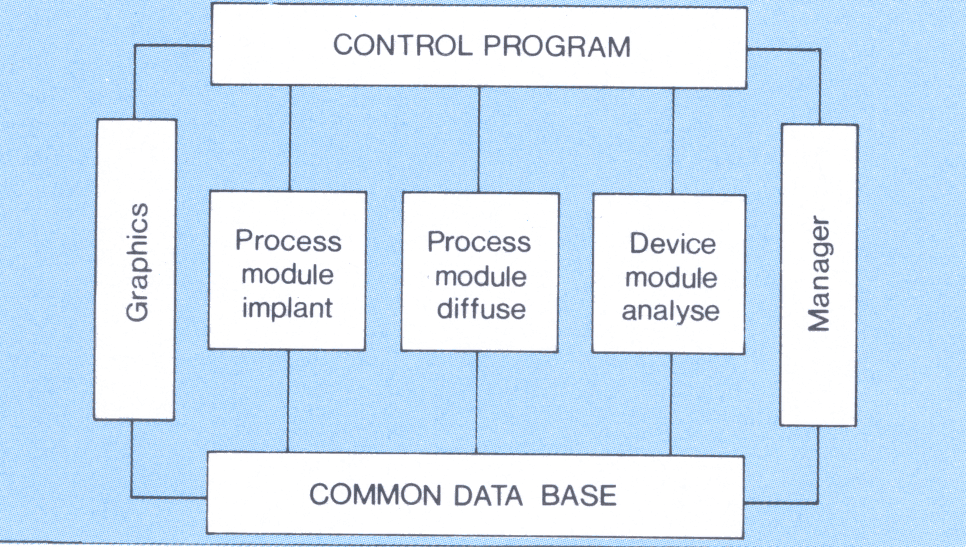

A diagram of the initial overall structure of TAPDANCE is shown below. RAL provided the binding elements - the contents of the boxes on the outside, and the device simulator module, with the other kernels written by university partners.

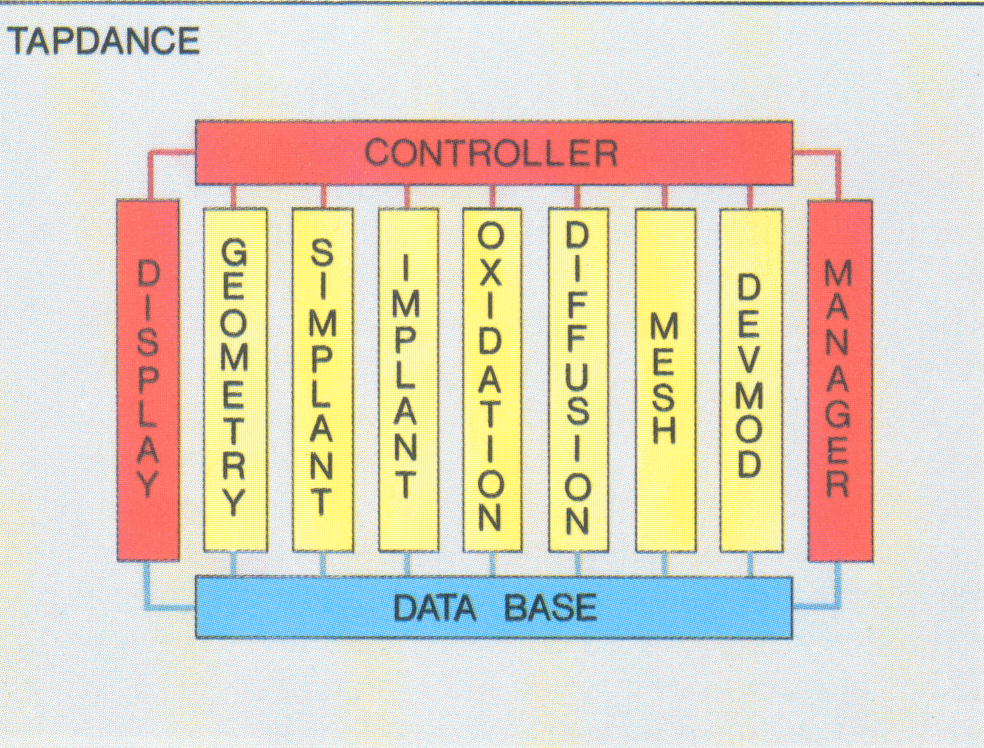

TAPDANCE, the Alvey Process and Device Analysis Command Environment, was an integrated computational modelling environment which enabled the process/design engineer to simulate all the steps involved in making and operating a semiconductor device within a single piece of software. RAL was responsible for the overall design of the system which consisted of a shell of basic software (database, database manager, command parser, graphics post-processor and an overall controller) and a number of kernels which performed the various simulation tasks (geometric specification, ion implantation, diffusion, oxidation, mesh generation and device modelling). The system eventually looked like:

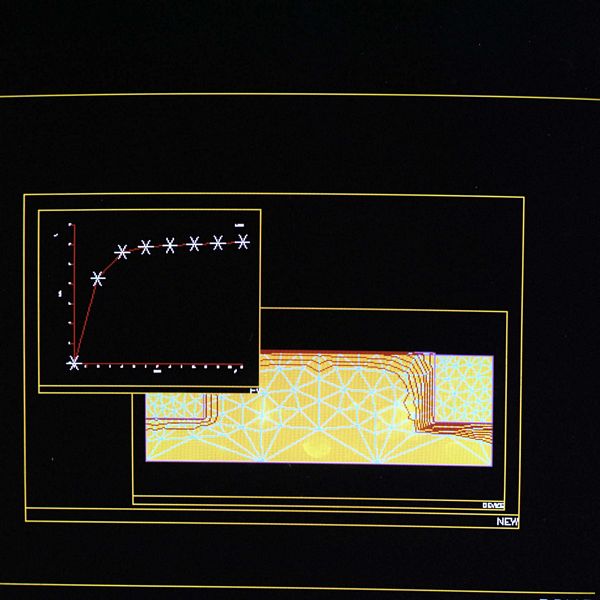

RAL provided the shell, geometry, mesh and device modelling kernels plus a simple implantation kernel, SIMPLANT. The other, more sophisticated, processing kernels were provided by university partners. Three modules were provided by university partners Implantation (Kent), Diffusion (Reading) and Oxidation (Swansea). RAL's SIMPLANT simulated ion beam implantation into any target made of semiconductor device fabrication materials. A typical target consisted of irregular abutting regions of silicon, silicon oxide and silicon nitride as shown below.

The project was targeted at an integrated approach to process and device modelling for 1 µm CMOS and bipolar technologies. The priority was to provide sophisticated and accurate modelling of critical process steps in a form which allowed somebody with minimal specialist knowledge to use the TAPDANCE environment. To aid this, a comprehensive HELP system was included.

DEVMOD, the RAL device modeller, solved the fundamental semiconductor device equations with the current transport given by the drift-diffusion model. The material model allowed for varying semiconductor composition, and was a basis for future modelling of heterostructure semiconductor devices. The emphasis initially was modelling silicon.

The device equations; Poisson's equation and the current continuity equations were solved by a simultaneous solution method, with a decoupled approach used for the initial solution guess. The program made use of a number of state-of-the-art features: the device domain was discretised by a triangular finite-element mesh that possessed the DeLaunay property. This allowed for arbitrary geometrical problems to be catered for. The linear system of equations made use of the ICCG and CGS solvers. (ICCG was based on one developed by Chris Greenough and CGS was written by Dr P Mole of GEC.)

A set of benchmark 2-dimensional problems were run on the system and the results compared with data from a variety of sources. Good agreement was achieved. The ability to solve the on-state problem (ie. when current is flowing in the devices) was added later.

The DISPLAY module was initially quite simple but John Ashby introduced the capability to produce isometric plots based on a general triangular finite element mesh using hidden line and hidden surface algorithms developed at University College Swansea. With the arrival of RAL-GKS at level 2b, zooming was added. Additional commands were added to enable the user to draw results of simulations such as the I-V curves.

TAPDANCE was released to a number of university and industrial sites. The system ran on both PRIME and VAX computers. Software integration and validation was the responsibility of John Ashby assisted by Raymond Fawcett.