In May an additional 500K bytes of main core store was added, making a total of 1 M bytes main core plus 1 M bytes of LCS. Four extra magnetic tape decks were added so that the installation now has 4 High Density (1600 BPI) 9 track tape drives, 3 Dual Density (800 BPI/1600 BPI) 9 track tape drives and one 7 track drive. These are attached by a selector sub-channel to the high-speed multiplexor. At the end of the year work was in hand to install a second magnetic tape control unit and another selector sub-channel.' (This will reduce the possibility of conflict between jobs accessing magnetic tape.) Early in the year the magnetic drum was brought into operation and allows fast access to much used system data sets.

Towards the end of 1970 the 2311 (small) disks will be replaced by a second set of 2314 (large) disks.

The extension to Building R1 provided a much needed increase in space for the central computer installation. The computer room was extended to allow for the increase in machine size, and the amount of working space and office space for operations staff in the reception area was increased. In addition a spacious data preparation area was provided, and also room for programmers to work in the reception area where there is access to a library of manuals and the data preparation equipment.

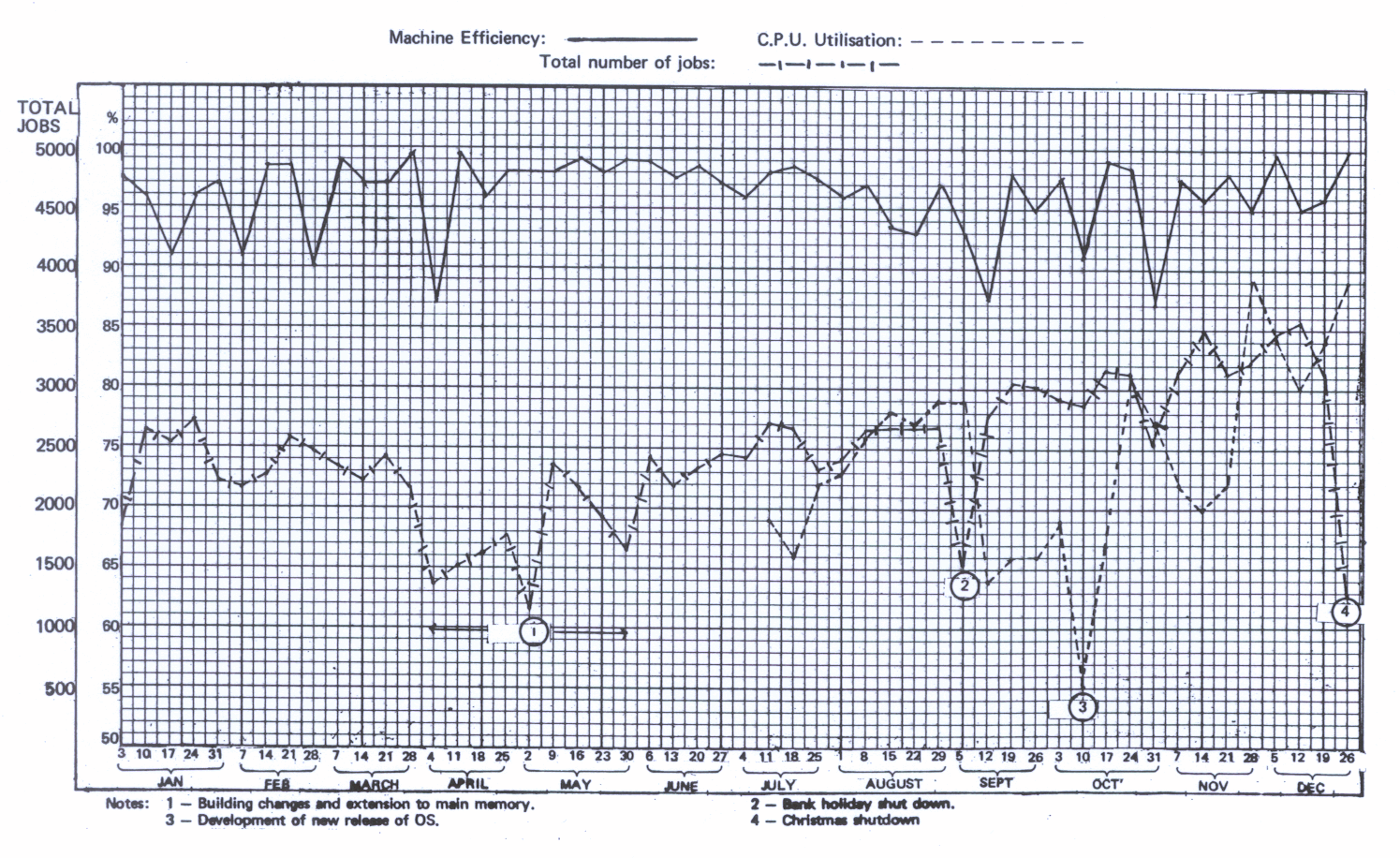

As a result of these modifications, it is now possible to run four batch streams in addition to the on-line work. Allocating one stream to CPU-bound production jobs has increased the weekly average CPU efficiency to over 80% without affecting the turn-round of short jobs, the average turn-round on prime shift being about two hours. The extra magnetic tape drives allow tapes to be loaded in advance and considerably improves the operation of the computer. The total number of jobs per week has increased from about 2500 to about 3500.

The MFT2 operating system continues in use. In August, release 17 of the OS was installed. Its main advantages were the ability to put more system modules onto the drum, and the ability to split partitions between main core and LCS. A consequence of the latter facility is that low priority partitions in LCS are now possible. Economy in the use of main core by long-duration low-activity jobs (such as graphics jobs) is made possible by running part of the job in LCS. Unfortunately full use could not at first be made of the facility because of system troubles in re-defining partitions.

A test batch, representative of the work load of the Laboratory, was constructed to allow comparisons of performance between different computers; it was run during the year on an IBM 360/85. The possibility of attaching keyboard terminals to the system is under consideration. The terminals would allow users to update files and enter jobs into the batch stream. Various existing systems such as CRBE, APL are being evaluated.

A program has been written to analyse the output from the IBM MUSIC Accounting facility. From this a weekly analysis of machine usage is made, by Division and by project and this information is given a wide circulation. The accounting program also provides very detailed information about the efficiency of the system, and the use made of the various system devices. This has been used in conjunction with IBM's AMAP program to construct the system data sets in the most efficient way possible.

The PPE package obtained from CAP, has been used on several long running production programs to pinpoint highly used parts of the program. Throughput can be improved, sometimes quite dramatically, by recoding these parts of the program.

Routines have been written which improve the efficiency with which 7-track tapes written on other computers can be handled. They are particularly valuable in reading tapes containing large numbers of faults due to having been generated under adverse conditions.

The Computer Introductory Guide and Reference has just been published to provide a comprehensive guide to the system facilities, and pointers to the source of information necessary for using them.

The library of standard catalogued procedures has been extensively revised, new procedures invented to enable users to submit jobs with as few control cards as possible, and a new library created of special-purpose procedures for groups or individuals. Bulletins have been issued describing these improvements, and giving guidance on the response of the operating system to errors made during the development of new programs.

The main on-line applications work of the Laboratory is centred around the coupled IBM 360/75 plus Honeywell DDP-224 computer complex. The DDP-224 controls the following equipment:

The DAEDALUS operating system, which has been developed at the Laboratory, is used to control the complex. It allows the transfer of data and messages between user programs running in the 360/75 and the devices attached to the DDP-224. All devices can be operating at the same time.

The complex is maintained and developed by a small support section of four and is scheduled for production operation for 97 hours per week. Availability of the complex as a whole has averaged better than 98%. During the year the OLX link has been transferred to a direct memory access channel to improve the efficiency of data transfer. In addition a multiplexor for connecting several Tektronix 611 storage tube displays has been developed. A detailed schematic layout of the complex is shown in figure 94. Detailed reports on DAEDALUS and items (i)-(iv) are given below.

The DAEDALUS on-line system has operated reliably throughout the year. Normally 70-80 hours of production is achieved each week and for much of this time there is more than one user. The main users are HPD, CYCLOPS and the IDI visual display. The latter became fully operational at the beginning of the year when the software package to drive the display by the light pen was fully debugged. Since then the system has been used to reprocess bubble chamber and spark chamber events which fail the analysis program. Up to 30 hours per week has been used for this purpose. At the end of the year final checking of software necessary to add a Tektronix 611 storage display unit was being done. This would allow the display of graphical output containing a large number of points but will have no interactive facilities. Facilities have been provided to allow users to enter jobs into the 360 by commands from DAEDALUS typewriters. Development of this is continuing to make it easier to use, and more versatile.

Work has begun on an improved DAEDALUS system which will be able to control many satellites. The first two computers to be added would be an IBM 1130 computer which is to be used as a terminal facility in the experiment Hall and the DDP 516 which will control HPD2. Later the existing IBM 1130 which controls the rough digitizers will also be incorporated in the system.

The HPD has been used this year for measuring film from two experiments in the CERN 2-metre hydrogen bubble chamber.

Antiproton film, exposed during 1966 and later, was measured intensively from January-July; by early August 76,000 events had been measured (all of 2-prong).

CYCLOPS is a flying spot digitizer used for measuring 35 mm spark chamber film. It scans the film with the image of a fine spot (about 20 microns across) generated on the face of a high-precision CRT. During 1969 it has had another full year of automatic operation, running under the DAEDALUS system for up to 20 hours per day using a 62K byte main core partition in the IBM 360/75 and 48K bytes of large core store. In production, CYCLOPS can measure up to 600 frames per hour where the frame measures 35mm × 100mm. Averaged over the full running time it reaches a figure of about 300 frames/hour and measures between 10,000 and 30,000 frames per week dependant largely on the availability of film. Binary picture numbers are decoded on-line; film positioning and the data are checked before digitized co-ordinates are written to 9 track magnetic tape on the IBM 360/75 for later off-line analysis.

During the year a fully operational system has evolved enabling diagnostic and production running to be performed within the same program. Operators using commands from an on-line typewriter can change the mode of operation and the values of selected variables in the program to enable problems with film and hardware to be diagnosed and overcome. New facilities making the system more automatic and more reliable have been added with the result that the system can now run virtually unattended for hours at a time.

Two experiments have been measured on CYCLOPS during the year. A Daresbury experiment on e-p scattering has been completed. This involved the measurement of some 100,000 events. Magnetic tapes of digitized data were stored and sent to Daresbury for complete analysis.

Measurements on film from the Nimrod experiment on the leptonic decay of neutral kaons was continued and a further 300,000 events have been measured.

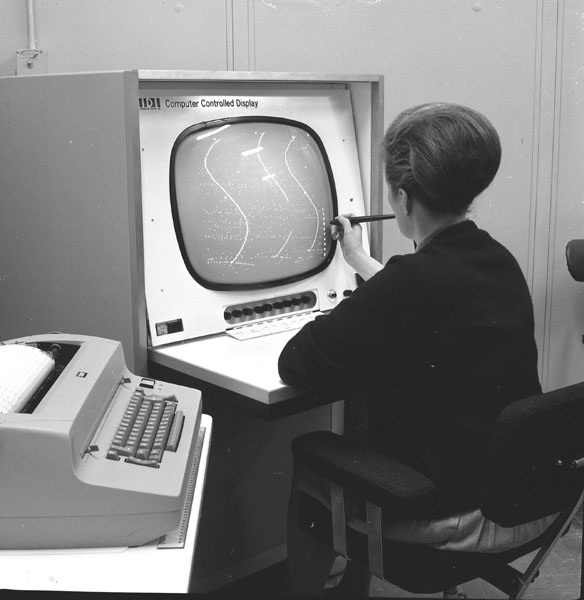

A set of computer programs has been written for rescuing bubble chamber events which, having been measured on HPD, fail in the Geometrical reconstruction programs. Selected regions of HPD digitizings of these events are displayed on an IDI computer controlled display, and by means of a light-pen, an operator controls the selection and accurate measurement of tracks. The results of these actions are displayed superimposed on the track digitizings, and can be modified or accepted by means of control characters, or light-buttons on the screen. When satisfactory, the track points are written to disk, to be merged at a later stage with the originally successful events.

These events have failed principally because of pattern recognition errors, the commonest causes of which are superfluous tracks very close to, or crossing the required tracks, and small scatters which cause incorrect determination of track curvature. Digitizings within a narrow road (640 microns wide on film) about the bad tracks are stored on magnetic tape, together with the co-ordinates of the three rough digitizings, and the track master points found by the automatic pattern recognition programs.

A batch of these tracks are transferred to disk and then displayed. The three views of a track are displayed side by side, and by means of the light buttons the operator selects which views require attention. With a single view on the screen, the operator either deletes some of the original master points, or causes a simple filtering of the track guided by points selected with the light-pen. New master points are displayed and can be accepted or changed. When satisfactory the coordinates of the new points are written to disk.

Over 100,000 track views have been displayed and patched up, corresponding to 20,000 failed events from anti-proton and K- film in the CERN 2 metre chamber. Measuring rate is about 100 tracks per hour, and the display is operated up to 10 hours daily. Of the bad events (which are about 20% of the total measured by HPD) between 50% and 75% are subsequently successful, the remainder being mostly very faint tracks or bad roads.

A film has been made of the patch-up system in action, and has been shown at the 1969 HPD meeting at Amsterdam where it was well received. Copies of the film have been borrowed by CERN, Dubna (USSR) and Argonne (USA). A set of programs is being written for patch-up of events measured under minimum guidance where only the vertex of an event is pre-digitized.

A similar system of programs is under development for patch-up of failed events from the CYCLOPS spark-chamber film device, where the tracks are straight and the problem is one of recognising tracks in two views by means of the spark structure. The spark co-ordinates and widths are displayed for the two views and by means of the light-pen, the operator can redefine end-points and correlate pairs of tracks.

Attached to the DDP-224 is a parallel data communications link which allows data collected by small computers in the Nimrod experiments halls to be transferred into the 360/75 via the DDP-224 (the distance is some 300 metres). Up to five computers can be multiplexed on to the link. During the year the main users of the facility have been the University College group collecting data for the K8 experiment. Data for the experiment was collected by a PDP8 and written to magnetic tape. During 'beam-off' times on Nimrod the data on the tapes was transferred via the link to the 360/75. The data was checked and partially analysed and then written to tape in compressed form. In all some 100 magnetic tapes containing some 4 million events were transferred via the link for this experiment.

The rough digitizer system which provides guidance measurements for the HPD system is now operational using six machines. Three of these are D-Mac and three Rutherford Laboratory IPD co-ordinate measuring tables. These are all connected to an IBM 1130 computer and data is collected in the computer, checked and then stored on a disk store. At a later stage this data is transferred to disk storage on the IBM 360/75 via an electronic data link. Usually this transfer of data takes place once a day and when sufficient data from a particular roll of film has been collected for HPD a further merging program takes the data from the 360 disk and puts it on to magnetic tape in a form ready for HPD programs.

The system is operated continuously for 124 hours a week and produces some 3-4000 events in that time. To increase the output a further six machines using Mangio Spago digitizers have been built and the electronics connecting those to the 1130 computer is currently being commissioned.

A supervisor program for the 1130 has been developed to allow the overlapped operation of all the devices and to sort data into a form suitable for data checking programs; since this is now operating satisfactorily it is being extended to handle up to 15 devices.

Data checking programs have been interfaced to the supervisor and, in the first phase checking has been limited to logical and format errors. Operators are informed of any errors via a typewriter which is supplied to each measuring station. Further co-ordinate dependent checks are being developed to improve the quality of the data and a system for the on-line calibration of machines is currently being devised.

The Track Analysis Maintenance Section of Engineering Division is now responsible for all the machines used in the measurement of bubble and spark chamber film. An additional 11 machines (of 3 different types) used for spark chamber films have been taken over for maintenance and for the incorporation of new digitizing systems. Machines for bubble chamber film now number 19 (8 different types) with the addition of 4 three channel projector machines using a modified Mangio Spago digitizing system connected on-line to the IBM 1130 computer. 2 Vanguard three channel machines are on order, and 2 Duff machines have been transferred to Durham University.

The scanning and rough digitizing machines are now housed in a suite of adjacent laboratories, with the workshop in close proximity. These changes have enabled reliability and throughput to be increased, as required by the gradual introduction of 24 hour scanning.